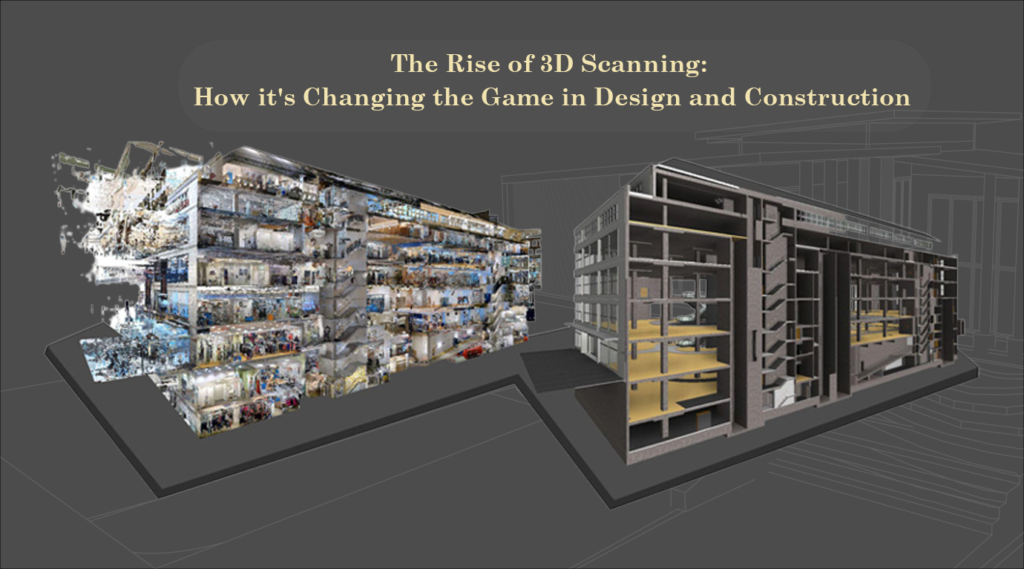

The Rise of 3D Scanning: How it's Changing the Game in Design and Construction

Are you fascinated by the transformative power of technology in shaping our world? Then, get ready to be blown away by the latest innovation that’s revolutionizing design and construction. Yes, 3D scanning is taking center stage and disrupting traditional methods of manufacturing and building. From architects to engineers, everyone is leveraging this game-changing technology to create intricate designs with precision accuracy. So, fasten your seat belt as we explore how 3D scanning is rising to prominence and transforming the way we approach design and construction.

What is 3D Scanning?

three-dimensional scanning is the process of analyzing and collecting data on the shape and appearance of an object in order to create a digital 3D model. This technology has been around for centuries, but recent advances in laser scanning and imaging software have made it more accessible and user-friendly than ever before.

There are many different applications for 3D scanning in the construction industry. It can be used for documenting as-built conditions, verifying dimensions and geometry, creating clash detection reports, and generating accurate BIM models. It can also be used to create prototypes orURMs (unreinforced masonry) of buildings or parts thereof prior to construction. The potential uses for this technology are limited only by the imagination of the user.

3D scanning is changing the way we design and build by making the entire process more efficient and accurate. With 3D scanning, there is no need for manual measurements or drawings – everything can be done digitally. This not only saves time but also reduces opportunities for errors. In addition, 3D scans can be used to create virtual reality models which allow users to “walk through” a space before it is even built, giving them a better understanding of the finished product.

History of 3D Scanning and Its Growing Popularity

Since the early 1990s, 3D scanning has been used in a variety of industries to create digital models of physical objects. Early adopters included the automotive and aerospace industries, which used 3D scanning to create accurate models of car parts and aircraft components for design and engineering purposes.

The late 1990s saw the introduction of SLA (stereolithography) 3D printers, which could produce physical objects from digital files. This technology made it possible to quickly and easily produce prototypes of new products, paving the way for mass customization and shortening the development cycle for new products.

In the early 2000s, 3D scanning technologies began to be used in the architecture, engineering, and construction (AEC) industry for as-built documentation, clash detection, and facility management purposes. The adoption of Building Information Modeling (BIM) in the AEC industry created a need for more accurate as-built data, which could be provided by 3D scanning.

Since then, 3D scanning has become an essential tool in the AEC industry. It is now commonly used for heritage preservation, facility management, additions and alterations (A&A) projects, quantity surveying, as-built documentation, site layout and grading, interior mapping and navigation, code compliance analysis, forensics investigation, accident reconstruction, virtual reality applications, and more.

The popularity of 3D scanning is only expected to grow in the coming years as more businesses realize its potential and Benefits of 3D Scanning for Design and Construction

3D scanning has revolutionized the design and construction industry, providing a faster and more efficient way to capture data and create accurate models. There are many benefits of 3D scanning for design and construction, including:

- Increased accuracy – 3D scanning is able to capture data with incredible accuracy, making it perfect for creating detailed designs and models.

- Increased speed – 3D scanning is much faster than traditional methods of data capture, meaning projects can be completed quicker.

- Reduced costs – 3D scanning can save money on project costs by reducing the need for costly manual labor or expensive equipment.

- Improved safety – By removing the need for workers to be in close proximity to dangerous work sites, 3D scanning can help improve safety on construction projects.

- Enhanced collaboration – With the ability to share data easily and quickly, 3D scanning can help improve communication and collaboration between designers, engineers, and contractors

How to Use 3D Scans for CAD/BIM Models

The use of 3D scanning technology has grown exponentially in recent years, especially within the AEC industry. Designers and engineers are using 3D scans to create digital twins of existing structures and project sites. This allows for a greater level of accuracy when creating as-built drawings and models.

3D scanning can also be used to create parametric models that can be used for quantity takeoffs, clash detection, and other construction coordination tasks. The point cloud data generated by 3D scans can be imported into BIM software platforms such as Autodesk Revit and Autodesk Navisworks.

There are many different types of 3D scanners on the market, each with their own advantages and disadvantages. It is important to choose the right scanner for the job at hand. For example, laser scanners are best suited for measuring large objects or spaces, while hand-held scanners are more portable and ideal for scan projects that require a high level of mobility.

When it comes to data processing, there are two main methods: direct processing and indirect processing. Direct processing is when the point cloud data is processed into a usable format without any manual intervention. This method is typically quicker and easier, but it can result in lower-quality data. Indirect processing is when the point cloud data is first converted into a mesh or CAD model before being processed further. This method often produces better results, but it is more time-consuming.

Potential Drawbacks of Using 3D Scans in Design and Construction

Despite the many advantages of using 3D scans in design and construction, there are also some potential drawbacks to consider. One such drawback is the cost of 3D scanning technology. While the cost of scanners has fallen in recent years, they remain a significant investment for many companies. In addition, the cost of skilled labor to operate the scanners and create accurate models can also be a barrier to adoption.

Another potential drawback is the accuracy of 3D scans. While advances in technology have greatly improved the accuracy of 3D scans, they are still not perfect. For example, small objects or features may be missed by the scanner or inaccurately represented in the resulting model. This can be problematic when trying to use 3D scans for precise measurements or construction drawings.

It is important to remember that 3D scans only capture an static snapshot of a space or object. They cannot capture dynamic processes such as people moving through a space or machinery in operation. As such, they are best used in conjunction with other data sources such as traditional surveying methods and photographs.

Examples of Successful Implementation of 3D Scanning in Projects

There are many examples of successful implementation of 3D scanning in projects. One example is the use of 3D scanning to create as-built drawings for a construction project. This can be used to verify that the construction project is proceeding as planned and to identify any potential problems.

Another example is the use of 3D scanning to create a virtual model of a building or structure. This can be used for planning and design purposes, or for creating a virtual tour for potential customers or clients.

yet another example is using 3D scanning in reverse engineering applications. This can be used to recreate an existing product or part or to improve upon it. In this way, 3D scanning can help businesses save time and money while still maintaining a high level of quality control.

Future Outlook of 3D Scanning Technology

The scanning technology used in construction and design is constantly evolving, and the future of 3D scanning looks very promising. Here are some of the ways that 3D scanning is expected to continue changing the game in these industries:

1. Increased accuracy and detail

2. Faster scan times

3. Lower costs

4. Greater flexibility

Conclusion

As the technology for 3D scanning continues to advance, it is clear that 3D scanning is going to play an increasingly important role in design and construction. By using this tech, designers can quickly capture intricate details or concepts that would otherwise take a long time to draw by hand, and builders can create amazing projects with unprecedented speed and accuracy. It’s only a matter of time before 3D scanning becomes widely used across many industries on a daily basis!

Popular Posts